A significant milestone on the path to climate-neutral building materials and the future competitiveness of the industry

End of May, the first CO₂ was successfully captured at the Brocēni cement plant using a pilot-scale carbon capture unit from the Norwegian company Capsol Technologies. The CapsolGo® demonstration unit will operate in test mode until the end of the year, capturing around 2 tonnes of CO₂ daily. This marks an important step in SCHWENK’s broader decarbonization strategy across its European operations.

“We at SCHWENK have come a long way through extensive analysis, studies, R&D processes and impact assessments to reach the point of the first CO2 captured,” says Reinhold Schneider, Chairman of the Board of SCHWENK Latvija and Managing Director of SCHWENK Northern Europe. “Considering that cement is the base of the whole construction and building materials value chain and at the same time accounts for around 8% of Latvia’s CO2 emissions, SCHWENK is strongly committed to launch a full-scale carbon capture plant in Brocēni by 2030. This test phase brings us one step closer to that”.

The CapsolGo® pilot plant is part of a broader technology evaluation program within the SCHWENK Building Materials Group. It has already been tested at the Akmenė site in Lithuania and will now be tested for seven months in Brocēni. Based on the gathered information and feasibility studies, the final investment decision is planned for 2027. A full-scale carbon capture plant at the Brocēni cement plant could then start to operate at around 2030 and capture around 800 000 tonnes of CO2 annually, aiming to reach net-zero emissions in the cement production. In this case, it will be one of the largest single industrial investments in Latvia in decades.

SCHWENK Latvija is the first industrial manufacturer in Latvia to start testing carbon capture technology and equipment. Decarbonization efforts at the Brocēni cement plant have been ongoing since 2020, with feasibility studies and comparisons of potentially available technologies carried out under the guidance of various international experts.

Brocēni cement plant is already one of the most environmentally friendly and modern in Europe. Over the past 14 years, CO2 emissions from cement production in Latvia have been reduced by 37%, and investments to further reduce the impact and improve efficiency over the last five years amount to €71 million. Around 70% of Brocēni’s production is exported to Estonia, Sweden and Finland. In the Nordic countries, there is already a strong demand for cement with a reduced CO2 footprint, so market conditions are also an important driver for change.

More information

Antra Savleviča

SCHWENK Latvija Communication manager

+371 26422891, antra.savlevica@schwenk.com

The Annual Award Ceremony of the Employers’ Confederation of Latvia took place on November 14, 2024. The largest employers were awarded in 10 different categories, highlighting their contribution to the country’s priority areas and achievements in business.

SCHWENK Latvija received the award in the category “Excellence in Business 2024” in the subcategory “Investment in the well-being of the company’s employees”.

Within the framework of of the measure 1.2.1.2.i.1. “Increasing energy efficiency in business (including the transition to the use of renewable energy technologies in heat supply)” of investment 1.2.1.2.i. “Increasing energy efficiency in business (including the transition to the use of renewable energy technologies in heat supply and research and development activities (including bioeconomy))” of 1.2. reform and investment direction “Improving energy efficiency” of European Union Recovery and Resilience Mechanism Plan

SCHWENK Latvija will promote the independence of the energy resources necessary for the company by creating a solar panel power station on the territory of the Brocēni cement plant with a total active power of inverters after connection installation of 5.0 MW (installed capacity of solar panels – at least 6.3 MW). The solar panel power plant is planned for partial self-supply of the plant, where in normal operating mode 98% or more of the electricity produced by this plant is expected to be consumed in the plant itself. After the completion of the project in the first 12 months after the installation and commissioning of the solar panel system, incl. connection to the AST network, it is planned to produce at least 5652 MWh of electricity, thus achieving a reduction of greenhouse gas emissions by at least 616.07 tons of CO2 per year.

As a result, after investing in renewable energy technologies, the company will be both more sustainable and competitive, as well as reduce the impact of external factors in energy resources procurement.

On January 10, 2024, the company concluded an agreement with Nord Solar SIA for the construction of a solar panel power plant, while on May 14, 2024, a loan agreement No. 078980/01 on the issuance of a loan for the implementation of the project with the conditions of applying the capital discount.

Total project costs: EUR 4,125,547.38 (of which direct costs – EUR 3,409,543.29)

European Union funding (in the form of a capital discount): EUR 1,003,480.25

Duration of project implementation: 01.2024–08.2025.

#NextgenEU, #InvestEU

At the conference “Digitalization of the work environment: taking care of yourself and others” organized by the State Labor Inspectorate and the European Agency for Safety and Health at Work, we shared our good practice in the processes of digitization of occupational safety and the implemented continuous improvement measures.

The purpose of the good practice award competition Golden Helmet was to demonstrate a way for the employer to implement innovative and effective measures to prevent work environment risks related to the use of digital technologies in the workplace, including the implementation of digital technologies to prevent work environment risks.

The 2024 occupational health and safety good practice awards Golden Helmet were presented to: YIT LATVIJA as the award winner in the small company category – for digitization processes in occupational health and safety monitoring in construction sites, and Stora Enso Packaging as the award winner in the large company category – for the use of digital tools and artificial intelligence for the improvement of the culture of the working environment and the development of risk awareness. Congratulations to the laureates!

The autumn forum “The Golden Helmet – 20! Labor protection superheroes” was held, which sought answers to the questions why labor protection specialists choose their profession, how it affects and changes them, and how their work can change society and the performance of companies.

On the occasion of the 20th edition of the “Golden Helmet” labor protection good practice competition, those present were treated to a delicious festive cake.

13 employers joined the health protection and occupational safety initiative “Mission Zero” and signed the Mission Zero Charter. Consequently, Mission Zero gathers 115 employers, who together employ almost 60.5 thousand employees, and four informative supporters.

The “Mission Zero” initiative sets a common goal – to make health and safety as the company’s priority values both in every stage of core business and in interaction with society, reducing the number of deaths at work and as a result of external conditions related to it, significantly reducing the number of accidents at workplaces, aiming for zero and preventively implementing measures to protect and preserve the health of employees.

In cooperation with Riga Technical University Development Fund, we support young people from Saldus and Brocēni counties who see their future in their native region and want to get secondary professional or higher education in one of the professional technical or higher education institutions in Latvia.

This year, after evaluating the applications received in the SCHWENK Latvija scholarship competition, three scholarships have been awarded instead of two.

Scholarships in the amount of 200 EUR for university students were awarded to students studying at the University of Biosciences and Technologies – Toms Ķempelis, who studies Biosystems Machinery and Engineering, and Jānis Sproģis, who studies Machine Design and Production.

A scholarship in the amount of 100 EUR was awarded to Alens Jakševics, who is studying mechanical engineering at the Ventspils Technical School.

This year, we met with our stakeholders in an online format.

We are happy for more than 60 of our cooperation partners, customers, representatives of the community, state and local government institutions, with whom we looked at the company’s sustainability goals and what we have achieved so far.

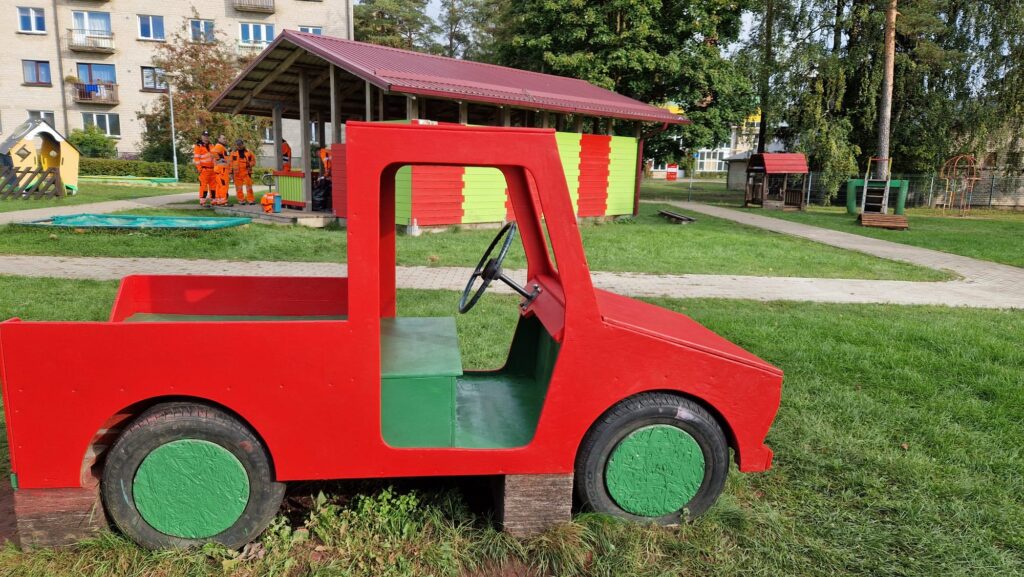

SCHWENK Charity Day has passed for good deeds and positive emotions. In order to make the joy of playing not only brighter, but also safer, this year we went to the Brocēni preschool educational institution “Mūsmājas”. As part of the day, we renovated several outdoor landscaping elements, painting them and replacing the worn parts with new ones.

Sincere thanks to the kindergarten children for the warm welcome and the prepared performance, it gave additional motivation for the planned work.

Krists Mertens has been appointed as Director of Decarbonisation and Energy Projects at SCHWENK Latvija. The newly created position will be responsible for implementing carbon capture projects at the Brocēni cement plant so that by 2030 the building materials industry in Latvia and Northern Europe can use cement with minimised CO2 emissions in the production process.

Mertens gained his experience in management and the energy sector in Latvia, having worked for Enefit for the last eight years. He has served on the company’s Board of Directors since 2018 and as Chief Executive Officer and Chairman of the Board since 2020. Previous work experience related to financial consulting and banking sector. Mertens holds a Bachelor’s degree in Engineering Economics from Riga Technical University and a Master’s degree in International Business Administration (MBA) from Riga Business School.

Reinhold Schneider, Chairman of the Management Board of SCHWENK Latvija and CEO of SCHWENK Northern Europe, points out that cement production is an emissions-intensive process, which is why the company has been making targeted investments for several years to reduce its climate and environmental impact. Our challenge for the next five years is to build carbon capture and related infrastructure and technologies at the Brocēni cement plant to provide cement with the lowest possible climate and environmental impact to customers in Latvia and export countries.

The Brocēni cement plant is expected to become the first industrial facility in the Baltic Sea region and one of the first in Europe to capture CO2 from the production process using innovative technologies, which will then be transported to specially adapted disposal sites, explains Mertens, pointing out that its benefits will be felt not only in the building materials and construction sectors.

SCHWENK Latvija Board Member, Director of Human Capital and Administration Linda Šedlere emphasizes that at SCHWENK Latvija we combine good and safe working conditions on a daily basis with equal treatment and an inclusive work environment for everyone who works for us. By embracing diversity management as one of our core employment values, we are able to attract employees from diverse backgrounds, increase productivity and foster an inclusive work environment.

Participation in the Diversity Assessment and the Family Friendly Workplace Assessment allows us to assess whether we are taking good enough care of our employees. This year, we are re-applying for the assessment to see our progress and whether we have been able to implement the experts’ recommendations.