SCHWENK launches the first carbon capture test base in Latvia

Experts emphasize the importance of developing a sustainable carbon management value chain

In the presence of the Prime Minister of the Republic of Latvia Evika Siliņa and other state officials, the first carbon capture test base in Latvia was opened at the SCHWENK Latvija Broceni cement plant.

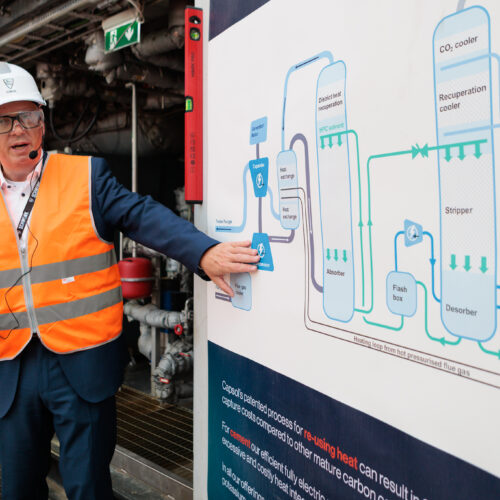

This year, several carbon capture technologies are tested in SCHWENK Latvija cement plant in Broceni to choose the most suitable solution both for the plant in Latvia and other SCHWENK Building materials group’s plants in Europe. It clearly demonstrates SCHWENK Building Materials Group’s commitment to decarbonize cement production in its operations across Europe.

The testing period is scheduled until the end of 2025, while the final investment decision is planned for 2027. Broceni plant in Latvia is among the first ones in the Group with full scale carbon capture starting around 2030, capturing around 800 000 tons of CO2 annually.

“Considering that cement is the base of the whole construction and building materials value chain and at the same time accounts for around 8% of Latvia’s CO2 emissions, implementation of carbon capture technologies in Broceni cement plant will be a game changer both for our industry’s impact on climate and our competitiveness in Northern European markets. Even more, it brings great opportunities for emerging industries, innovation and investment attraction to the Baltics,” says Reinhold Schneider, CEO SCHWENK Northern Europe and Chairman of the Management Board SCHWENK Latvija.

Along with technological and technical developments in the plant, it is crucial to work on building a sustainable carbon management.

“Latvia is a place where it is possible to have green production at the same time compete in international markets. And SCHWENK is a good example of this, opening the first carbon capture test base in Latvia. Cement production is not a simple process. This is one of the most difficult areas to decarbonize. But with ambitious targets, solid foundations are laid for reducing CO₂ emissions. And in the long term, CO₂ can become the basis of a new value chain, ” says Prime Minister Evika Siliņa.

“The opening of the CO₂ capture project in Broceni is a historic moment for Latvian industry and the environment. This demonstrates our determination to move towards climate neutrality while strengthening the economy, creating new jobs and introducing innovation. With this project, the SCHWENK plant strengthens its leadership on a European scale, but Latvia confirms that industry and the environment can be allies on the way to a more sustainable future for future generations,” says Jānis Irbe, Parliamentary Secretary of the Ministry of Climate and Energy.

“SCHWENK Latvia can now become a cornerstone, opening up opportunities for a number of new industries – carbon capture, transmission, storage and, most importantly, further use – both in the chemical industry and in food processing,” Jurģis Miezainis, Parliamentary Secretary of the Ministry of Economics, emphasized during the event.

Māris Zusts, Chairman of Saldus Municipality Council: “We, Saldus municipality, are very pleased with our entrepreneurs and SCHWENK Latvija activities. We are proud and grateful for what have been done. Climate neutrality issues will become increasingly relevant in the coming years, and this is a vivid example of how to approach work, nature and future generations responsibly. Thank you for that and we encourage you to keep it up.”

From May 2025 SCHWENK in Broceni has been testing a hot potassium carbonate technology CapsolGo® from Norwegian Capsol Technologies ASA, since middle of August, a physical approach using porous framework for catching CO2 molecules from Canadian Svante is installed. Along with on-site testing numerous studies and analysis are implemented to assess the performance of various technologies and potential investment needed for full scale carbon capture. “Our plant in Latvia is the one, where tail-end solutions are tested for the needs of the whole SCHWENK Building materials group. It not only proves that Broceni is a state-of-the-art production site, but also brings great added value to our local economy and creates attractive local workplaces for employees,” says R. Schneider.

Background information

SCHWENK Latvija is the leading building materials producer in Latvia, providing its customers with high quality cement, ready-mix and aggregates. Production is carried out in the only Latvian cement plant, which is also among most modern in Europe, five ready-mix plants and several aggregates quarries in Latvia. SCHWENK Latvija capacity of concrete deliveries are among the highest in Riga, providing stable deliveries also in challenging conditions. Company is a part of German SCHWENK Building Materials Group, has approximately 350 employees in Latvia.

SCHWENK Latvija is the first industrial manufacturer in Latvia to start testing carbon capture technology and equipment. Decarbonization efforts at the Brocēni cement plant have been ongoing since 2020, with feasibility studies and comparisons of potentially available technologies carried out under the guidance of various international experts. Apart from tests in Latvia, also an oxyfuel process technology is tested in SCHWENK Building Materials Group’s plant in Mergelstetten, Germany. That requires the construction of a new kiln line and is a part of the catch4climate project in the CI4C consortium.

Brocēni cement plant is already one of the most environmentally friendly and modern in Europe. Over the past 14 years, CO2 emissions from cement production in Latvia have been reduced by 37%, and investments to further reduce the impact and improve efficiency over the last five years amount to €71 million. Around 70% of Brocēni’s production is exported to Estonia, Sweden and Finland. In the Nordic countries, there is already a strong demand for cement with a reduced CO2 footprint, so market conditions are also an important driver for change.

For more information please contact:

Antra Savleviča, Communication manager SCHWENK Latvija

+ 371 26422891, antra.savlevica@schwenk.com